Project definition

We take a lot of time in this phase.

To achieve a perfect integration between machine and cabin, we develop a special partnership to our customers during the planning phase: at this point of the project, goals as well as tasks and deadlines are all clearly defined in order to be achieved step by step. This teamwork provides clear guidance and ensures smooth information exchange.

Design and planning

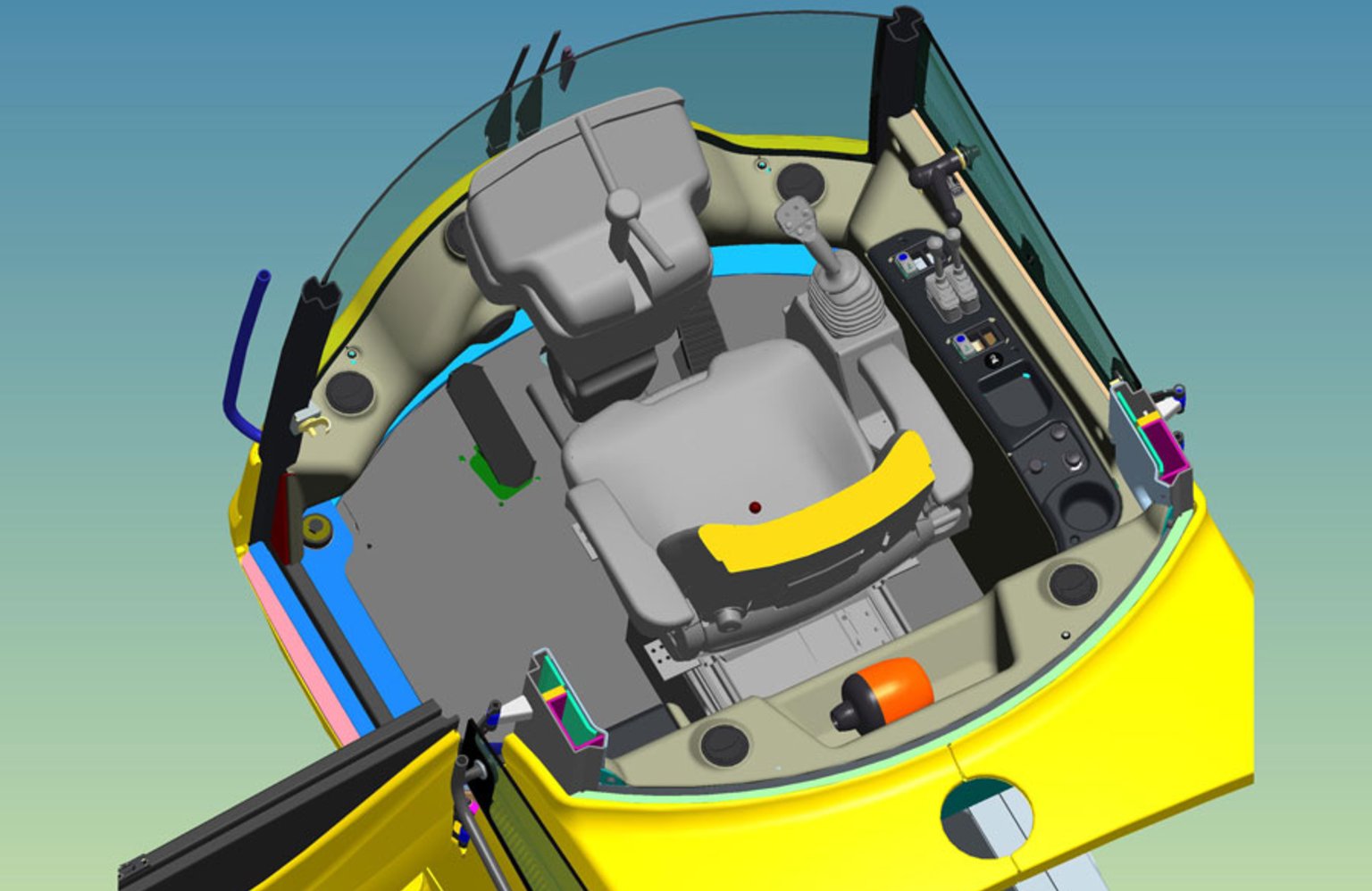

We are aware that factors such as design and aesthetics today are crucial elements for the final product. This is why our project office closely co-operates with a designer, who, at the initial phase of the project, generates a creative idea which will be further developed by our technical department.

While planning new cabin-types our technical department constantly tries to meet all of the customers requests by combining their needs with the machine's technical features and of course, the current market trends. In this way we are sure to offer the best solutions always improved in comfort, aesthetics and functionality.

Testing and certification

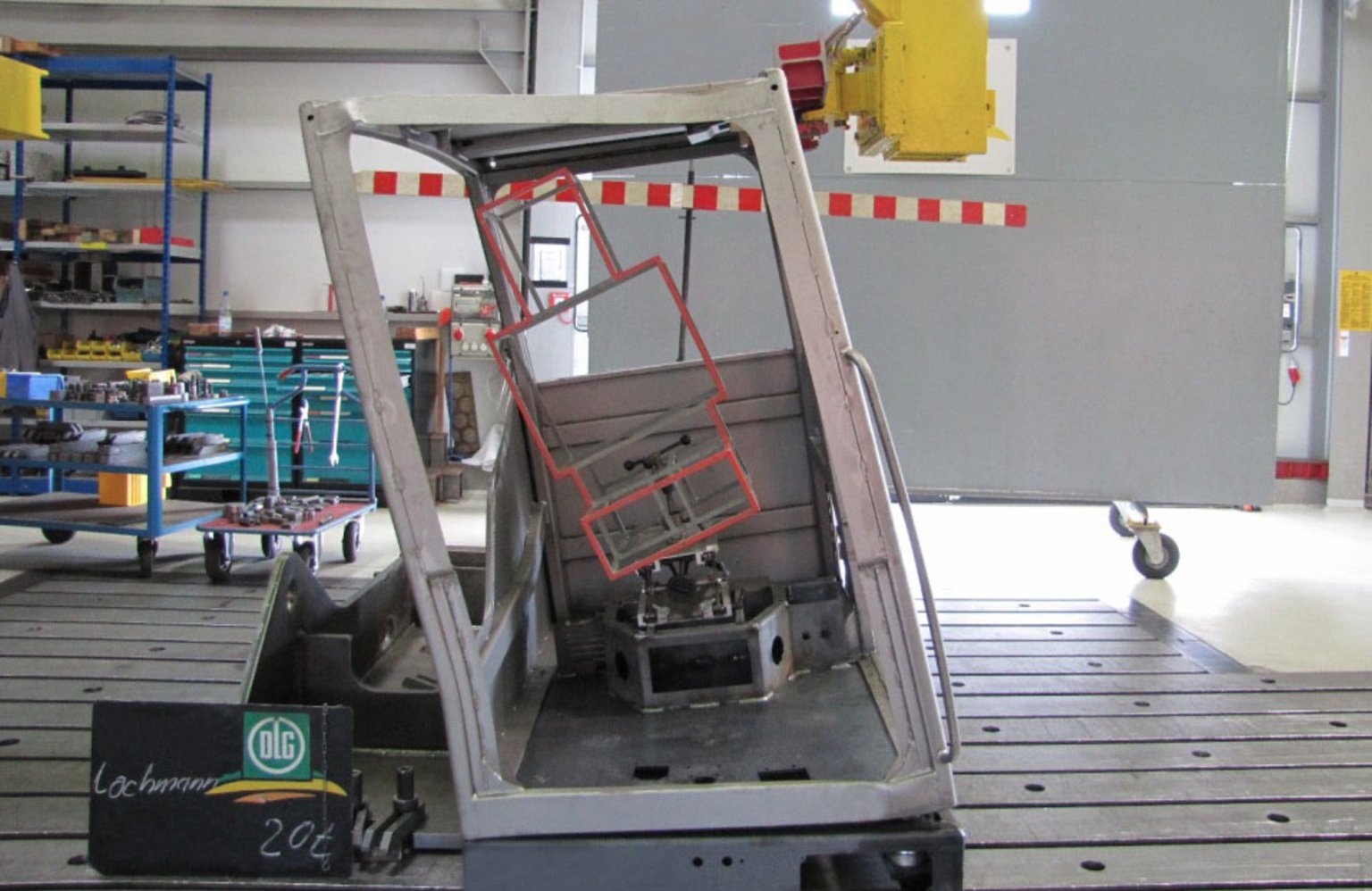

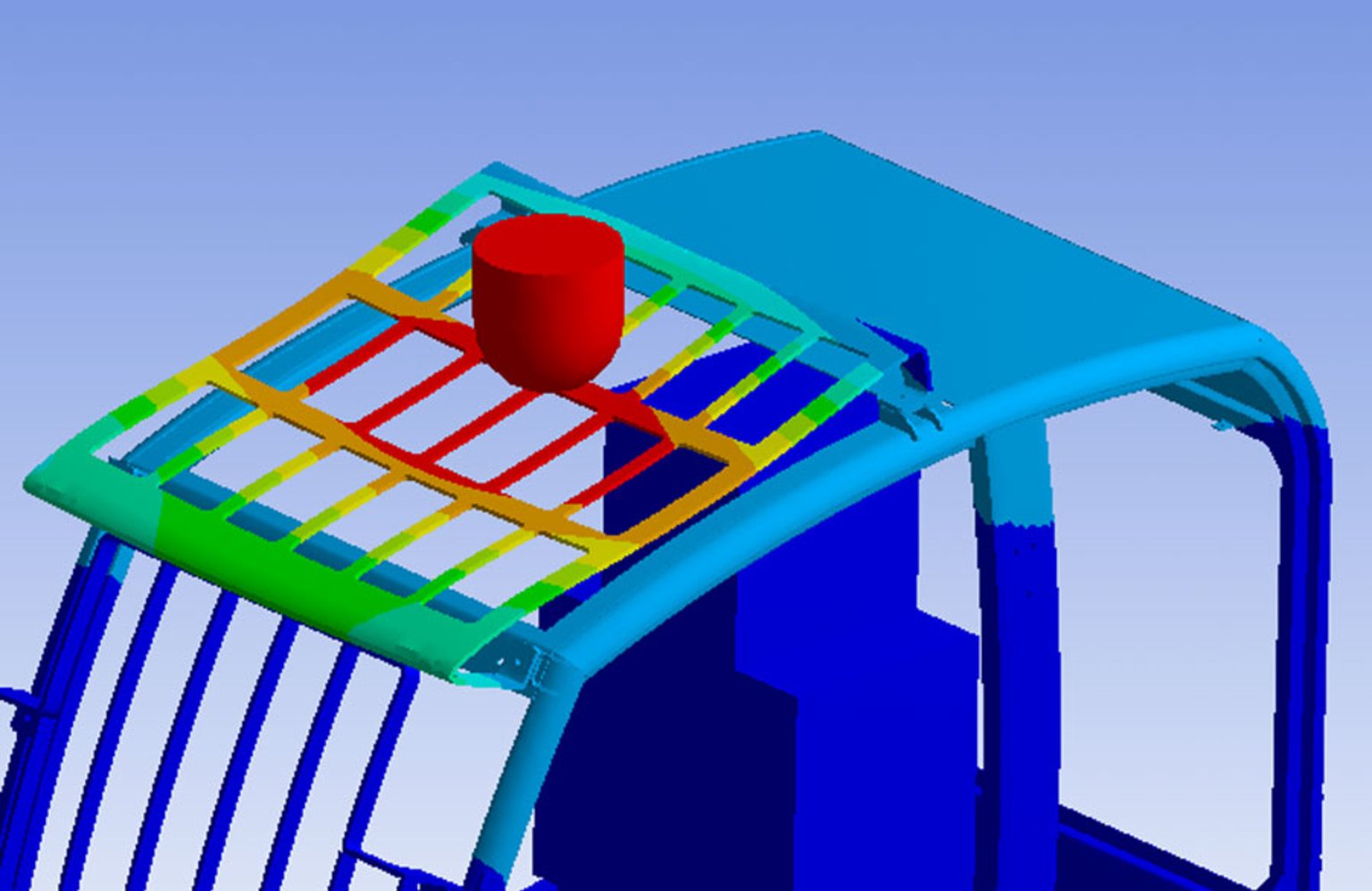

Carrying out tests on the cabin survival space are already routine for us.

Just to name the usual tests:

- ROPS test (Roll-Over-Protective-Structure - against rolling over)

- FOPS test (Falling-Objects-Structure - resistance in case of heavy objects falling from above)

- TOPS test (Tip-Over-Protection-Structure - protection device against tipping over) and EOPS test (Excavator-Over-Protection-Structure - protection device against rollovers)

- OPS test (Operator-Protection-System - protection against penetrating objects)

Pressure tests

LOCHMANN CABINS is always up to date with regards to new directives and guidelines that guarantee the security and well-being of the operator who might get in contact with dangerous chemical components by driving agriculture- and forestry machines or self-driving sprayers. To keep up with our goal of maintaining continuous safety and quality, we plan and produce cabins corresponding to the European guideline EN 15695 – 1.2009 category 4. On request of the client, the cabins are undertaken a pressure test; this service is executed during the prototyping phase of the cabin, before the pre-production by our skilled and certified operators begins.

Noise and water tests

LOCHMANN CABINS strives to provide its clients with top-notch quality and safety products. Therefore, upon your request, we are glad to offer specific noise tests that comply to the 2009/76/CE directive (the noise level to which the driver of an agriculture- or forestry machine is exposed).

Every cabin produced by LOCHMANN CABINS is subject to a water test: this is executed in order to avoid any possible liquid infiltration into the driver's cabin.

Prototyping

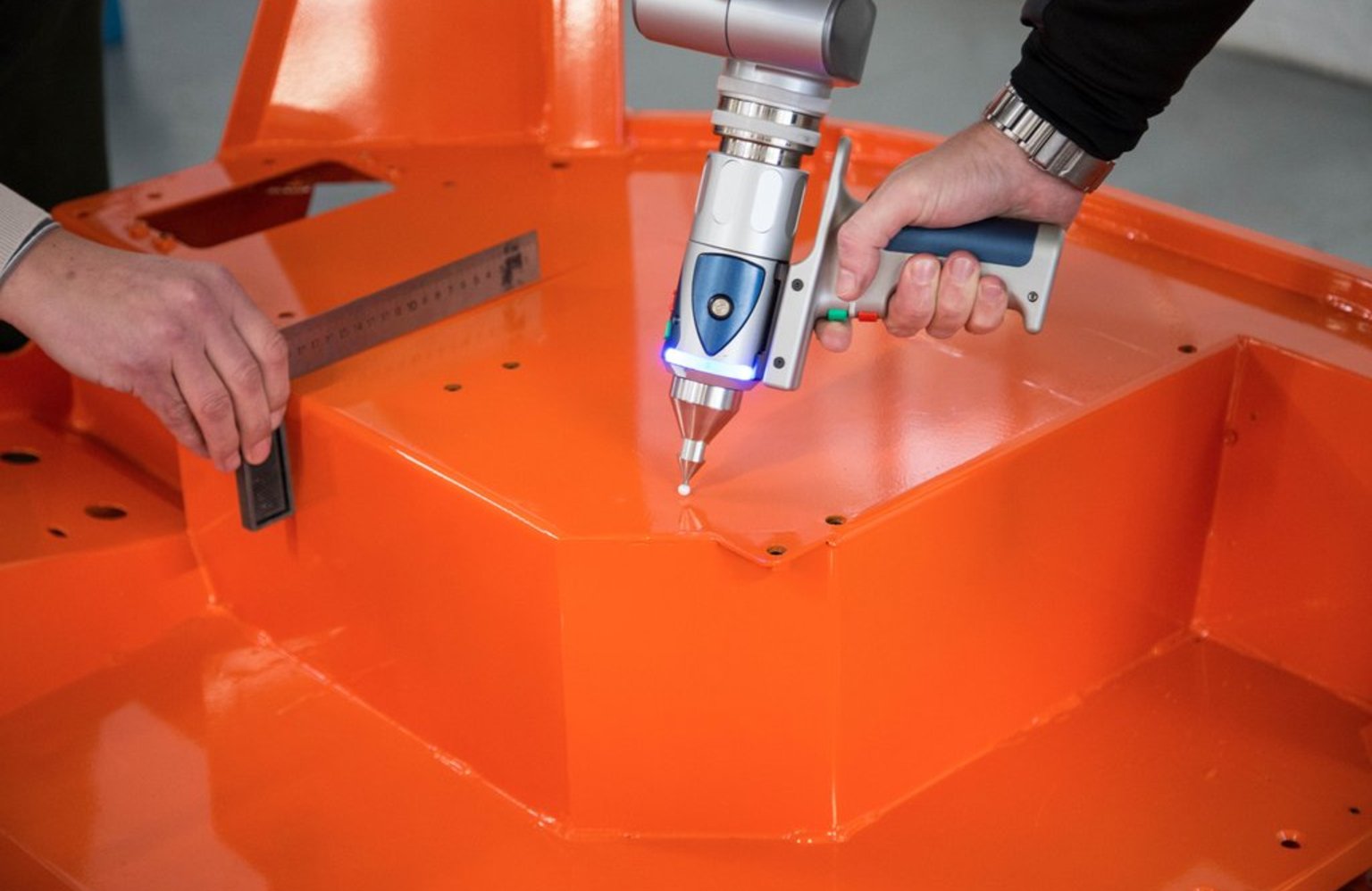

The realization of prototypes requires a close cooperation between the engineering office and the prototype department. By elaborating mock-up and cabin prototypes that are completely equipped, the customer has the possibility to visualize the final product. Thereby the technicians can perfect the smallest details of the cabin.

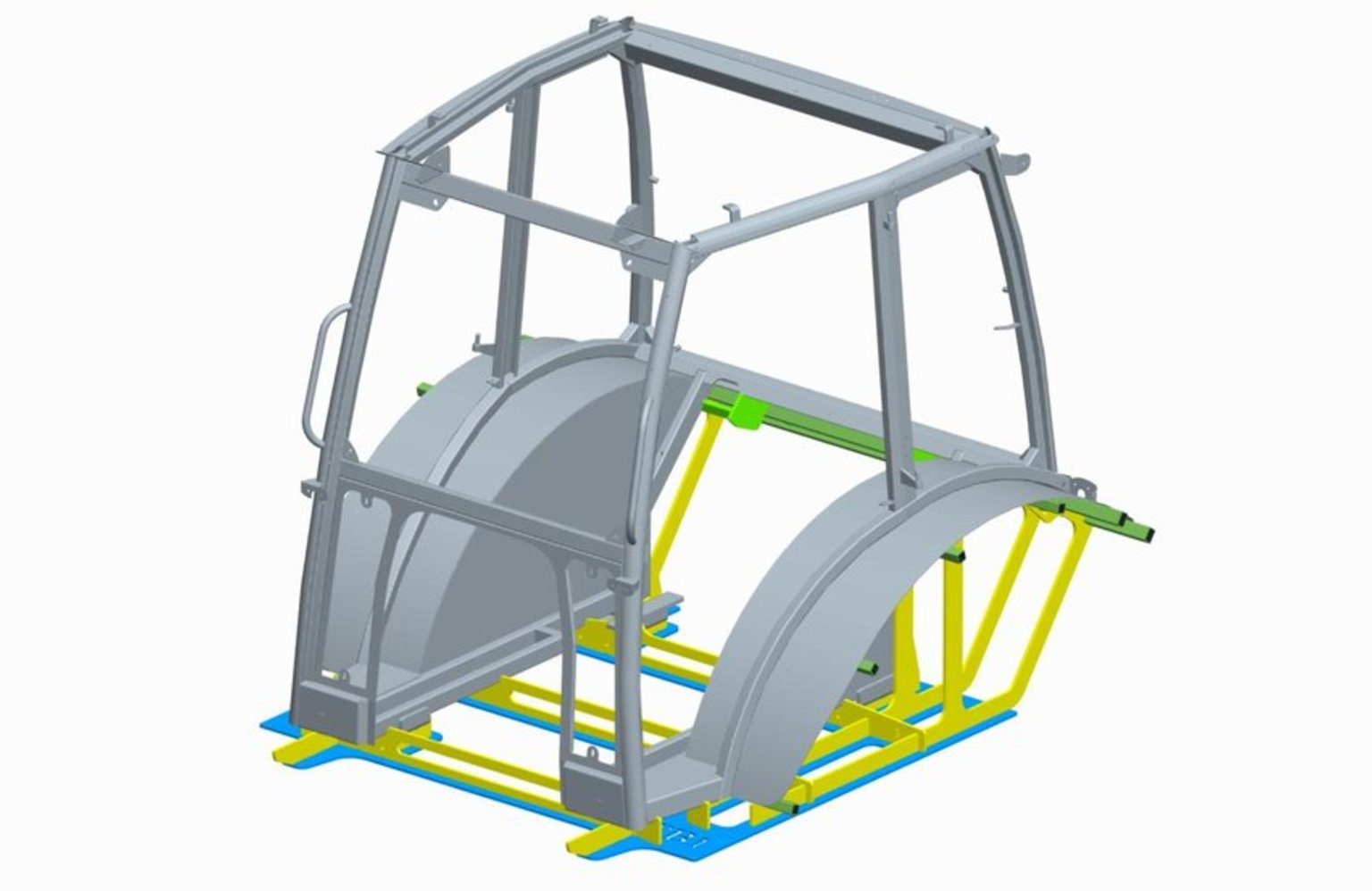

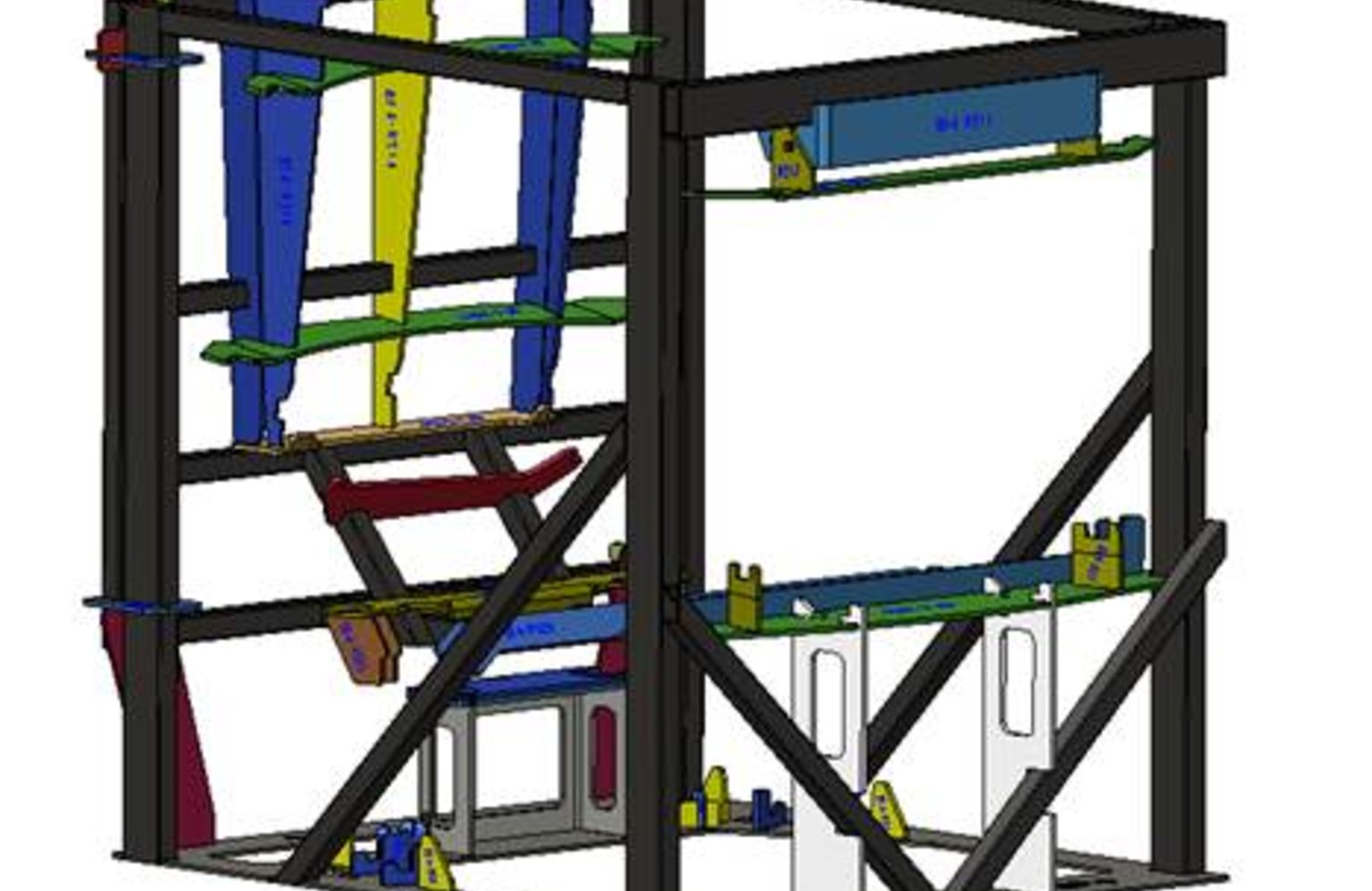

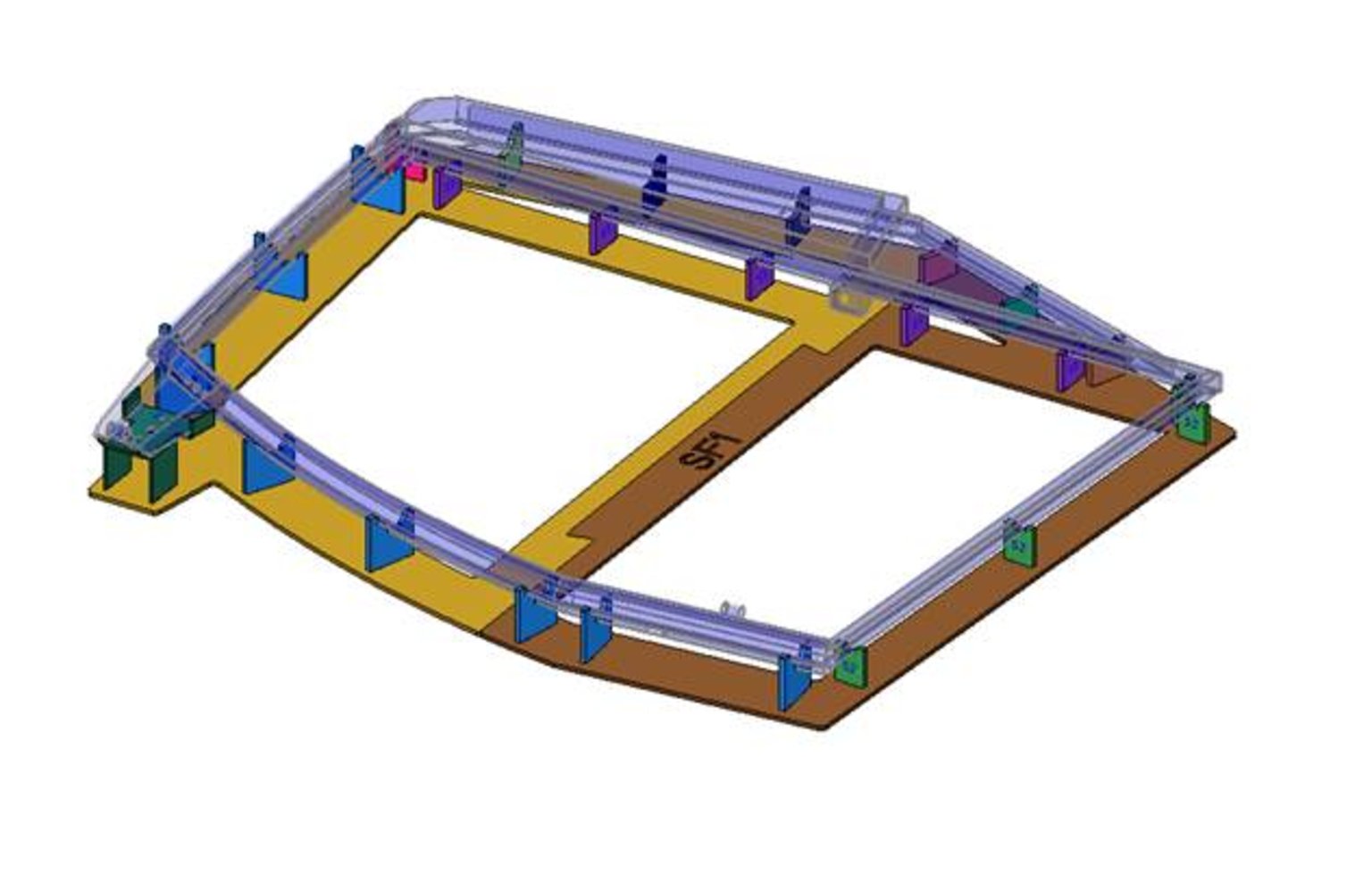

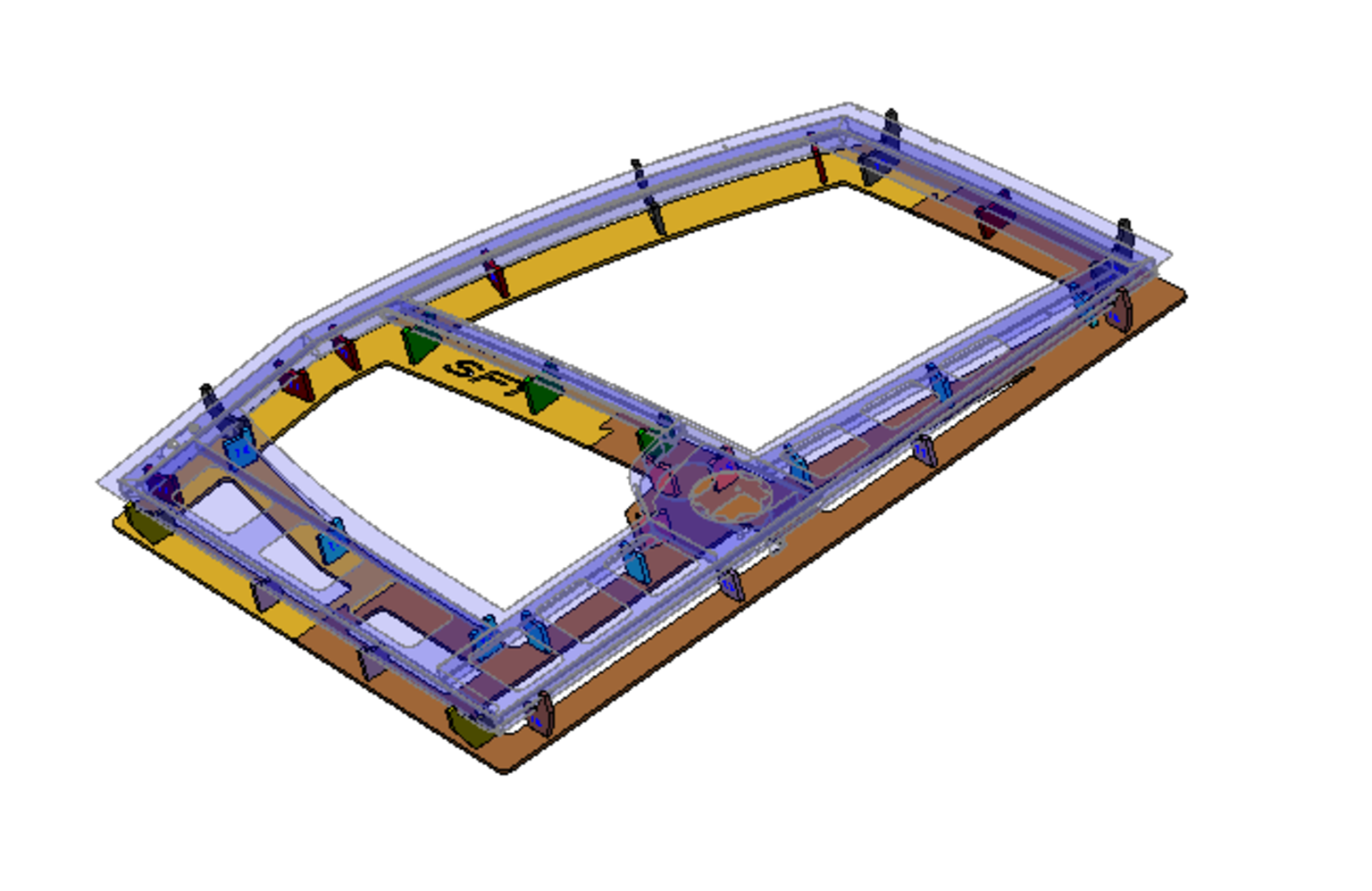

Tools

All of the tools used for the realization of the cabins are designed and manufactured by Lochmann.

This allows us to keep a check on the quality of the final product and also on the timing.

We produce 3 types of tools: welding jigs; moulds for glass; moulds for interior panels and roofs.